The China Tengzhou International Machine Tool Functional Components Exhibition was held as scheduled from October 31st to November 3rd. Our institute dispatched three technical personnel to attend the exhibition specially, with a clear core goal: focusing on the problem of machine tool manufacturers' dependence on imported bearings and providing targeted domestic substitution solutions on site.

Attend the exhibition with solutions: Turn R&D achievements into "problem-solving recipes" for manufacturers.

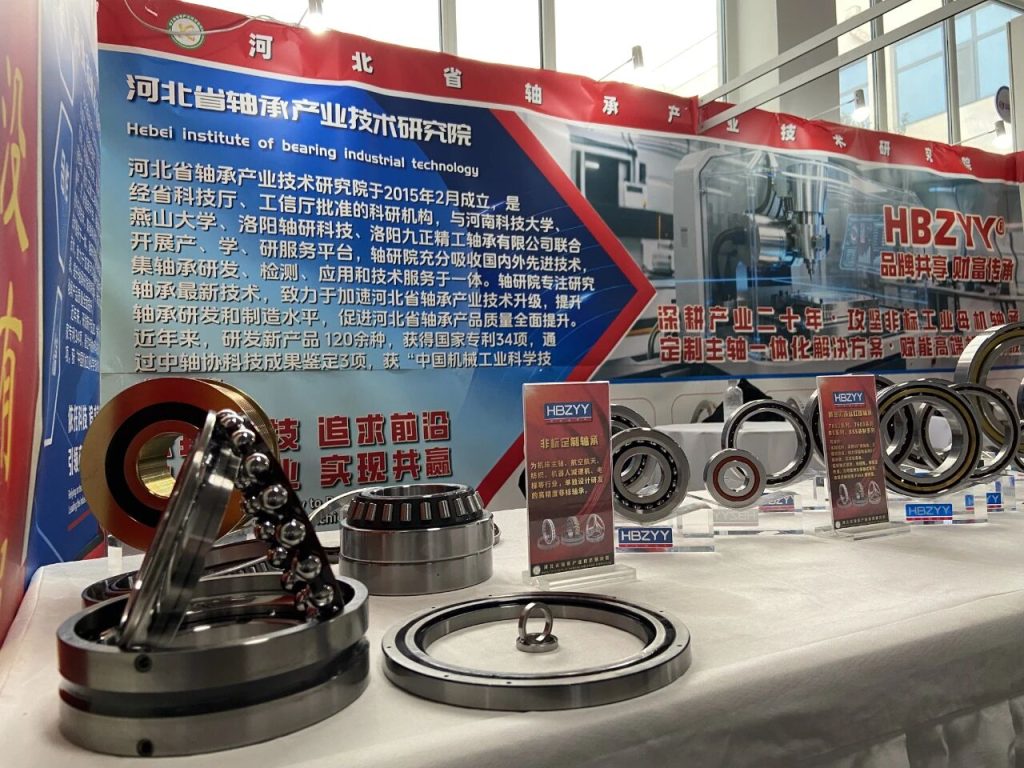

As the "heart" of equipment, the performance of machine tool spindle bearings is directly related to processing quality. For a long time, the dependence on imports in the high-end market has plagued domestic machine tool manufacturers with issues such as costs and delivery times. At this exhibition, our institute's team brought targeted and mature substitution solutions along with customized service capabilities, adhering to a "problem-solving" orientation throughout and conducting in-depth "one-on-one" communications with participating manufacturers.

As soon as the Technical Director of a Shandong-based machine tool enterprise arrived at the booth, he urgently put forward the core demand for spindle bearing substitution. Combining the enterprise's production conditions and actual needs, our technical team immediately demonstrated the achievements of the suitable substitution solution, explained in detail how the solution meets the operational requirements of its equipment, and analyzed the feasibility and implementation ideas of the solution one by one in response to key issues such as performance stability that the other party cared about. The clear solution explanation and professional response to needs made the Technical Director express his willingness to cooperate on the spot and agree to provide detailed parameters later to promote customized adaptation.

Solid Technical Support: A Breakthrough from "Technological Monopoly" to "Independent Controllability"

Manufacturers' trust stems from our institute's years of technical accumulation in the field of domestic substitution. To break foreign monopolies, we have built an independent full-link innovation system covering "materials – processes – finished products – services":

On the material front, we have jointly developed special bearing steel with top domestic iron and steel enterprises. Its excellent properties of high hardness, high temperature resistance and resistance to micro-deformation lay a solid foundation for the stable operation of bearings.

On the process front, we integrate the high efficiency and precision of intelligent production lines with the meticulous control of manual assembly, greatly improving product consistency and yield rate, and ensuring that every product can meet high-end application needs.

To meet the operating condition requirements of different machine tools, our institute has formed a diversified substitution solution matrix:

High-rigidity cylindrical roller bearings are suitable for heavy-load and precision spindle scenarios such as lathes, and can compensate for length changes during rotational motion.

Thrust angular contact ball bearings can build a stable axial force-bearing system, and achieve better results when used in combination with radial load bearings.

Beyond the Exhibition: Lifecycle Services Escort the Implementation of Domestic Substitution

"Participating in the exhibition is just the beginning. What we aim to do is truly implement the solutions and help manufacturers completely get rid of dependence on imports," said the technical director of our institute. For the intended customers contacted this time, the team has formulated a "three-step" service plan:

In the early stage, we provide free operating condition analysis and product adaptation suggestions.

In the middle stage, we support sample testing and parameter optimization.

In the later stage, we offer installation guidance and full-lifecycle technical tracking.

This trip to Tengzhou is not only a precise docking of technical solutions, but also a witness to the accelerated advancement of domestic bearing substitution. As a R&D institution focusing on bearing technology innovation, our institute has always taken "empowering the high-quality development of the machine tool industry" as its mission. We will continue to deepen industry-university-research collaboration, tackle key breakthroughs targeting common pain points in the industry, bring more cost-effective domestic bearings into production workshops, and equip "Made in China 2025" with reliable "Chinese cores".

Submit Request

PDF Request

Simply fill out the form below and the catalog will be available for download!